Laser Hardening

The goal of all metal hardening processes is to ensure a structural transformation of steel and cast iron materials with greater strength. First, the original ferritic-perlitic material structure is austenitized by heating, and then transformed into hard martensite by quenching. Laser hardening is the perfect solution for processing highly stressed, complex components. This is because there is practically no warping of the component during processing due to targeted heat input that is confined to local areas. You can even open up applications that would not be possible with conventional hardening methods such as induction or flame hardening using the non-contact laser process. Since the machining process can be controlled precisely, even geometrically complex and delicate components can be hardened. The result is surfaces that can be strongly stressed mechanically and chemically; they produce significant benefits in tool making, the automotive industry, and in agricultural technology.

How does the laser hardening process work?

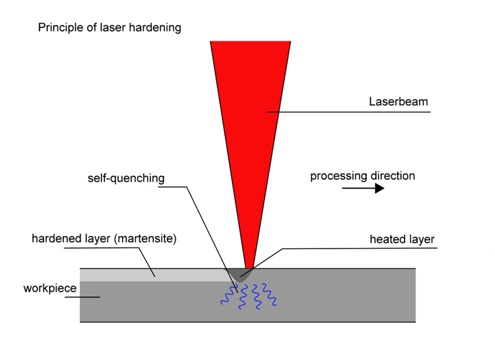

- In laser hardening, the skin of a carbon-containing workpiece made from steel or cast iron is heated up to just below the melting temperature – this is generally around 900 to 1400°C. Around 40% of the irradiated power is absorbed. The high temperature causes the carbon atoms in the metal lattice to rearrange (austenitization).

- When the nominal temperature has been reached, the laser beam starts to move, thereby steadily heating the surface in the direction of feed.

- As the laser beam moves on, the surrounding material cools down the hot surface very quickly in a process known as self-quenching. As a result of the rapid cooling, the metal lattice is unable to return to its original form, producing martensite. This results in a significant increase in hardness.

- The hardening depth of the outer layer is normally 0.1 to 1.5 millimeters, although on some materials, it may be 2.5 millimeters or more.

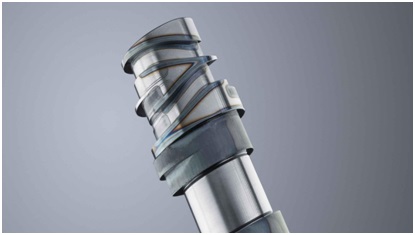

Case Hardening of a camshaft

The Service life of a camshaft is significantly extended by laser Hardening. Different levels can be processed in parallel due to the large depth of focus.

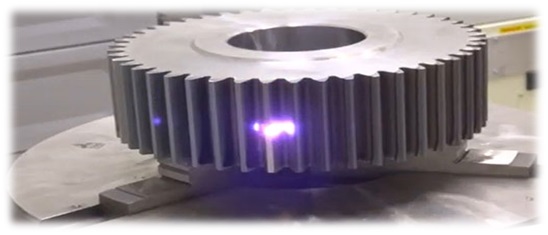

Gear Teeth- Laser Hardening

- Commonly the materials which are laser-hardened are plain carbon steels (AISI 1040, 1050, 1070), alloy steels (4340, 52100), tool steels, cast irons (grey, nodular, malleable).

- After Laser Hardening the hardness improved Exponentially to 65 HRC on the gear teeth with case depth of 2.1 mm