LASER CLADDING TECHNOLOGY

THE PROCESS

Laser-Powder-Cladding is a welding process where the surface of a metallic part is heated by a high power laser. By addition of filler material, a cladding layer is generated. The new materials strengthen and enhance the original component properties to lengthen its lifespan, thereby improving overall engine efficiency at a fraction of the cost of buying a new component.

RESEARCH AND DEVELOPMENT

Industrial application of Laser-Powder-Cladding draws for 3 years of research and development by Pruna and in cooperation with German universities to bring forth cutting edge technology firstly to automotive, Oil & Gas sectors. Central objects of research have been WC coatings. Beside a wide range of part from all kinds of industries, nowadays more than 2500 of Oil & Gas valves and 20,000/day automotive engine valves of various makes are produced by Laser-Powder-Cladding and successfully put back into full service targeting a zero claim policy.

The process offers the technical advantages:

- Metallic bonding of layers

- Very limited distortion

- Small heat affected zone

- Low effort in pre and post processing

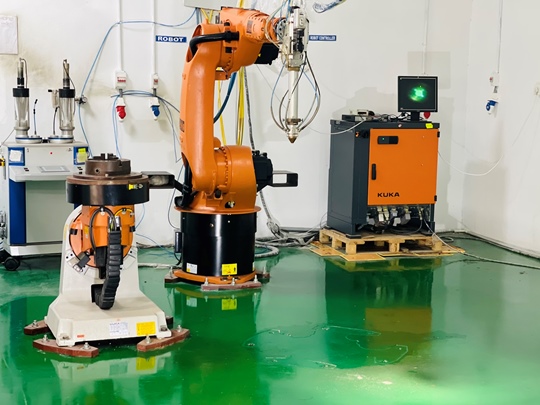

EQUIPMENT

- High-powered lasers, 1 unit

- High accuracy 6-axis robot for laser systems

- Turn tilt unit and adapters for various work pieces

- Mechanical workshop for machining

- Portable Hardness tester for on job inspections

- Support system for shafts up to 5 m in length

RELIABILITY

After extensive scientific tests, our processes have been proven to restore and recondition engineering components effectively and extend their lifespan after being put back in operation. Laser-Powder-Cladding is also DNV-GL approved.

COMMERCIAL ADVANTAGES

Through Laser-Powder-Cladding, we offer the following advantages, or what we deem as the r3:

- Reconditioning and enhancing worn areas and new contours to original sizes

- Reduced down times for manufacturers and charters requiring repairs

- Lower costs for reconditioning components

- Saving the environment by restoring old parts instead of replacing them entirely